Highlighting the fantastic January 2026 selection

Explore our first edition for 2026, filled with carefully selected coffees from six talented roasters who make up our January 2026 edition.

Seattle is known for many things. It’s rainy weather, big business and, of course, coffee. But the biggest US city in the Pacific Northwest is also famed for its long list of crafts, its gorgeous natural surroundings and its excellent links to other parts of the world.

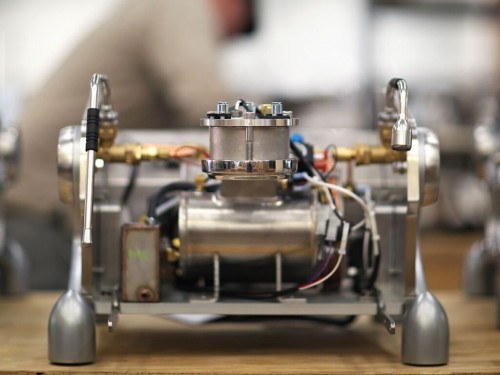

The latter list was actually the key reason why Canadian entrepreneur Jason Prefontaine chose Seattle as a place to start building his spectacular Slayer espresso machines. Regarded as one of the most advanced and customisable espresso machines in the world, the Slayer has slowly but surely been making its way into some of the world’s fanciest coffee bars, and this trend is most certainly not about to slow down any time soon.

During a recent visit to Seattle, I met with Slayer’s Marketing Manager Chris Elliott and after he gave me an extensive tour of the new facilities, we sat down for a chat about the company and the amazing things it has achieved so far.

The Coffeevine (CV): Hello Chris, how’s Slayer’s Instagram community today?

Christ Elliott (CE): Oh they’re good! They are super involved, which is great. It’s so nice to be in touch with so many coffee-aficionados the whole world over just through sharing pictures.

CV: There’s obviously a plethora of espresso machine makers out there but when you look at your closest competitors who do you think you’re really up against? Kees van der Westen for example?

CE: Yes, I think Kees is probably our closest competitor when it comes to what both of us aim for as companies. The construction quality of Kees’ machines is fantastic from what I have seen, and the design is really cool. Still, I think that is also one of the things that really sets Slayer apart. We have a really unique look and we offer tons of different options to truly customise our machines . You don’t get that with many other manufacturers.

CV: No. I think all you can change on Kees’ machines is minimal branding on the front or the sides of the machines.

CE: Exactly! But his machines still look spectacular. As you can see, everyone has a different approach. We allow our customers to request modifications, and sometimes their imagination is really out of this world. We’ve made machines with gold or leather casings for instance. They’ll definitely attract your attention.

[…] “all of our modification options are done locally. We have access to an incredible wealth of crafts like woodworking and painting.”

CV: Do you ever, out of interest, buy a competitor machine and take it apart in your workshop to see what it looks like on the inside?

CE: We haven’t bought any before but we have definitely snooped around at various coffee shops that have them to see if we can figure out if there are any obvious secrets, ha ha! I wonder if anyone else has ever bought one of ours for this purpose?

CV: How far would you go with regards to these customisation requests? Is there anything that you say you’d simply never do?

CE: We try to say yes more than no, and it’s definitely been a massive learning experience for us too. When the first customers came and asked for leather or gold modifications it wasn’t like we had a catalogue lying around that offered all these variables. For us, it’s as much a learning curve than for the partners who then help us make these modifications.

CV: When Slayer first launched, what were your expectations with regards to who’d actually buy one of your machines?

CE: Well, I wasn’t there then, but when I speak to the people who were here, it’s clear that no one anticipated the growth we experienced. We started here in Seattle but our owner is from Canada and in the beginning he would fly in from Calgary every couple of weeks to check on progress. It was really a tiny team then.

CV: Why wasn’t he building them in Canada?

CE: Seattle was just a better hub for manufacturing and all of our modification options are done locally. We have access to an incredible wealth of crafts like woodworking and painting. Seattle is also a big transport hub and really known for its coffee heritage, so it simply worked out better to build the machines here than in Calgary.

We had a lot of people from the industry who showed huge interest; baristas, roasters and what not, and they helped a great deal with providing feedback, helping to fine-tune the machines and to get the word out.

In the first year or two we sold a few dozen machines. These days we sell a several hundred machines a year. It’s been an incredible ride!

CV: How does a company like Slayer go out and sell those machines? Do you pro-actively approach coffee bars or do they come to you?

CE: Yes, it’s a mixed bag really. We get a lot of referrals from people who saw a Slayer somewhere and they then wanted the same for their own space, but the biggest chunk comes from social media. I don’t know if other espresso machine makers can say the same thing but our machines lend themselves very well to social sharing and that is how a lot of our customers actually find us.

The machines have real sex appeal, but we have also been able to go past the physical appearance of the machine and really explain to people on Instagram what makes these so unique.

CV: Is there any particular coffee chain or brand that has a huge amount of Slayers in its stores?

CE: The truth is that we mostly work through distributors who sell our machines to end customers, so in some cases we don’t even know where they end up. Our biggest markets are actually in Australasia because they’re growing at high speed. For espresso-based drinks anyway!

“We sold five super customised machines into Serbia last year for example, and that was really unexpected.”

CV: Which countries in particular?

CE: China, Japan, South Korea…

CV: China? What’s happening there?

CE: China is definitely one of our biggest markets and the distributor there has his own coffee chain that is really big. But, if you’re talking about one particular coffee brand that is committed to working with us, then it would probably be Revelator in the American south. They opened their first café last year and they’re super ambitious. They now operate cafés in Tennessee, Alabama and Georgia.

CV: And they roast themselves?

CE: Yes, they do. When I think about them, I kind of consider them to be the new Blue Bottle of the South. Counter Culture is the other one that is well known in the Eastern US,but they’re not as far south as Revelator. They’re more in New Orleans, Birmingham and Asheville.

CV: What’s the most unlikely place that operates a Slayer? I am thinking, maybe a Yurt somewhere in Mongolia?

CE: Ha ha! Not that I know of. But, we sold five super customised machines into Serbia last year for example, and that was really unexpected. We didn’t even know Belgrade had much of a coffee culture at all, so it was interesting to learn that someone out there really loved our machines. I mean, they wanted a glass casing, inside paint job, meticulous logo work and so on.

CV: What are your plans for the near future? You only recently moved into this new workspace and you’re still getting everything up to scratch, and you currently only have one model.

CE: Right. We have one model in three different sizes. We are always refining the way these machines work and at the moment we’re doing ‘housekeeping’ to get everything in order. Our staff is really growing a lot.

CV: How many people work here?

CE: Between 15 and 20 or so. But we’re bringing on a few new people. By the end of the year we’ll have 20 full-time staff members.

CV: How long does it take to become a qualified machine builder?

CE: You know it totally depends your their experience levels. Some people come here who have previously built espresso machines and for them it’s just a matter of adjusting the way they’re used to putting them together. For others it’s a whole new learning process that takes more time.

CV: What’s the main challenge you see for Slayer?

CE: Phew. Well, we’re a super small company in an industry that has many super small companies but for our size we’ve managed to carve out a nice chunk of social media following, which is really great, but sometimes you feel like you simply cannot keep up. I am sure there must be people out there who think our machines are made by this huge multinational, but the truth is we’re only 15 guys in Seattle making everything by hand.

CE: As a final question, where do you guys see the coffee industry going? I for one have seen a lot of very good developments across the world but not everyone’s interested in specialty coffee actually. Will there always be this gap between excellent and average?

CE: It’s really hard to say. I mean, in the US at least there’s been this real movement back to various crafts. People like things that are handmade and created with high quality ingredients. But whenever you say ‘movement’ you also imply it might just be a fad, so it’s difficult to predict.

I was quite taken aback the other day when a friend of mine posted a picture of Stumptown’s cold brew now being sold at Target. I mean it’s Target! It might as well be Walmart. They’re literally taking specialty coffee to the masses. I think it’s incredible!

CV: Thank you for your time!

To find out more about Slayer or to order your own, visit Slayer Espresso

Out of coffee? Visit our brand new online shop to buy freshly roasted coffees from some of our most favourite artisan roasters, and many other great products.

Explore our first edition for 2026, filled with carefully selected coffees from six talented roasters who make up our January 2026 edition.

Enjoy the delicious coffees from our December 2025 edition with this handy brew guide. Tried and tested by our roasters.

Enjoy the delicious coffees from our November 2025 edition with this handy brew guide. Tried and tested by our roasters.

Don’t miss this selection of fantastic local specialty coffee shops in Granada, one of Spain’s most charming cities that’s brimming with life

Subscribe to our newsletter for new box announcements, articles and special offers. No spam. Promise!

© 2025 All rights reserved The Coffeevine.